Published on July 20, 2023 by Shakun Singh

Introduction

Titanium is a structural metal that is light, strong and corrosion-resistant and is used in several industries, including in chemical processing, construction, aircraft and vehicles. Most of it is used by the aviation and defence sector (which accounts for around two-thirds of global demand) due to its high-tensile strength and durability. Rising defence spending across the globe is expected to be a major driver of market growth. Other major users of titanium are the industrial and medical sectors. Due to its superior performance as an alternative to carbon fibre and steel, titanium has gained greater commercial acceptance.

The titanium market was estimated to be worth about USD24bn in 2022 and USD44.7bn by 2032. This surge in value could be attributed to increasing geopolitical tensions between Russia, Ukraine and other NATO nations, leading to a significant rise in defence spending on a global scale. As a result, there is growing demand for modernising and upgrading defence equipment, particularly aircraft. Titanium, with its unique properties, plays a crucial role in meeting these requirements.

Aviation and defence: This sector uses both pure titanium and titanium alloys for a number of components. Titanium alloys account for the largest share of raw materials in the aviation market, followed by aluminium alloys. The aviation sector accounts for c.75% of the available high-grade titanium sponge. In addition to use in applications for airframes (undercarriage, fasteners and wing spars), it is also used in engines, blades and shafts.

Industrial: Titanium is widely used for engineering applications because it is corrosion-resistant, strong and light. It is 40% lighter than steel but just as strong. It is, therefore, used widely in this sector.

Medical: Titanium has low density and high strength and is corrosion-resistant. Therefore, it is used in dental and surgical implants such as denture frames and bases, rod connectors, orthodontic wires, hip joints, bone plates and pacemaker housings.

Others: These include energy, chemicals, automotive and shipbuilding. Titanium’s resistance to seawater and its high ductility, lightness and resistance to high temperatures are favourable for its use in these sectors.

Titanium supply

Since the Russia-Ukraine conflict started in February 2022, there has been a constant threat of sanctions and raw material embargoes on Russian companies. Russia’s VSMPO-AVISMA is the largest producer of titanium, accounting for 90% of Russia’s production, and supplies c.30% of the world's titanium, with a nameplate capacity of 34,000t/year. Western aerospace company Boeing sources about one-third of its titanium requirements, Airbus sources about half and Embraer almost its entire supply from Russia. Since the conflict, such large European and American companies have started to look for alternative sources of supply.

Japanese companies such as Osaka Titanium, Toho Titanium and ATTM have about twice the capacity of VSMPO in terms of titanium sponge tonnage and could fill the gap in demand left by VSMPO. US-based ATI and Howmet Aerospace are other companies that could take advantage of this situation.

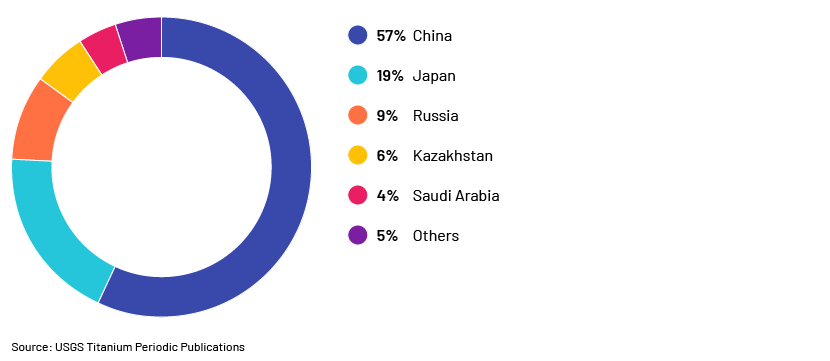

With growing demand for titanium, countries with the largest titanium sponge production capacity such as China, Japan, Kazakhstan and Saudi Arabia are expected to benefit the most.

China dominates the market in Asia Pacific and is expected to continue doing so.

The major suppliers of titanium sponge to the US in 2022 were Japan (82%), Kazakhstan (9%) and Saudi Arabia (7%).

Emerging trends in titanium use

Major trends expected to accelerate and increase demand for titanium:

-

Applications in sports and recreational activities

-

Growth in bicycle industry

Green hydrogen:

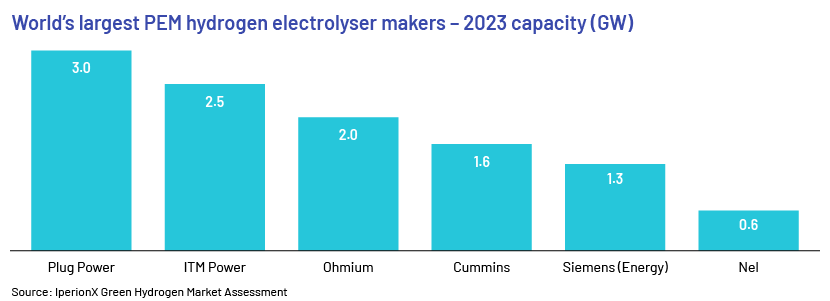

Titanium is an important component in proton membrane electrolysis and is used to make bipolar plates for proton exchange membrane water electrolysis. Hydrogen produced by the electrolysis of water is used to power houses and fuel cars, trucks and buses.

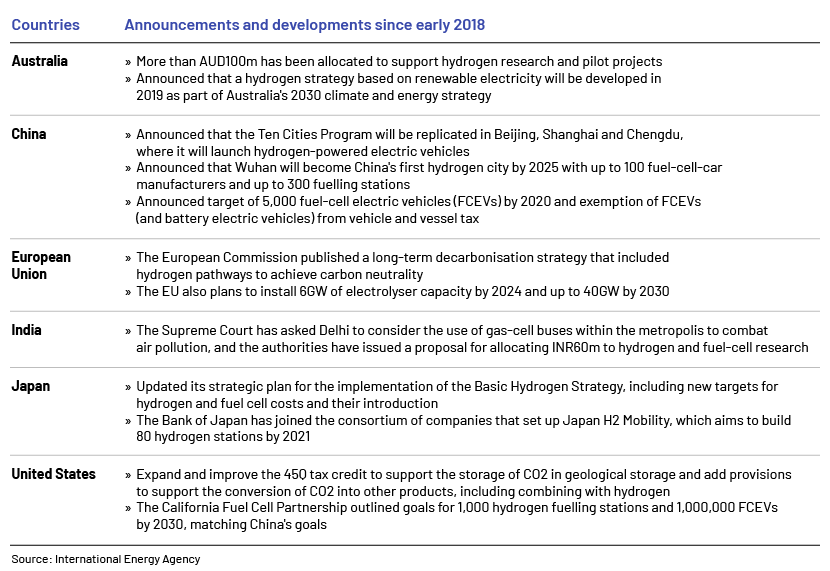

The use of hydrogen as a low- or zero-carbon fuel is considered critical to achieving global net zero ambitions. Close to 90% of the world's economies have plans or policies that support hydrogen. The following major countries had issued announcements enabling the development of hydrogen as a low- or zero-carbon fuel as of early 2018:

This indicates demand for titanium would increase as a result of government initiatives in the green hydrogen space. Global demand for green hydrogen is expected to be as large as the current global titanium market by 2040.

Applications in sports and recreational activities:

Titanium has had an increasingly large impact on high-speed ships, high-performance automobiles and other components used in smaller sectors in recent years due to its properties such as weight, strength, ductility and chemical stability. It also has excellent corrosion-resistant properties that help in environments exposed to seawater. Additionally, titanium products outperform their aluminium and steel counterparts in terms of fatigue and fracture strength.

The use of titanium alloys for ships (including submarines and naval vessels) is concentrated in Russia, the US, Japan and China:

-

Russia: Russian "Typhoon" class nuclear submarines have a two-hull structure. A total of 9,000 tons of titanium has been used in the double shell.

-

US: High-performance titanium alloys are used in ships such as nuclear-powered aircraft carriers, amphibious landing craft, landing craft and coastal exploration ships.

-

Japan: Japan uses pure titanium for pressure-resistant hulls in deep-sea vessels and commercial and fishing vessels.

-

China: China uses marine titanium alloys for hull structures, propulsion systems, power systems, electronic information systems, auxiliary systems and special equipment.

The high-speed shipbuilding and high-performance automobile sectors are expected to grow rapidly due to the ability of titanium alloys to operate at extreme temperatures, from sub-zero to over 600 degrees Celsius, making titanium alloys valuable in engine hulls and other applications such as ships and automobiles.

Growth in bicycle industry:

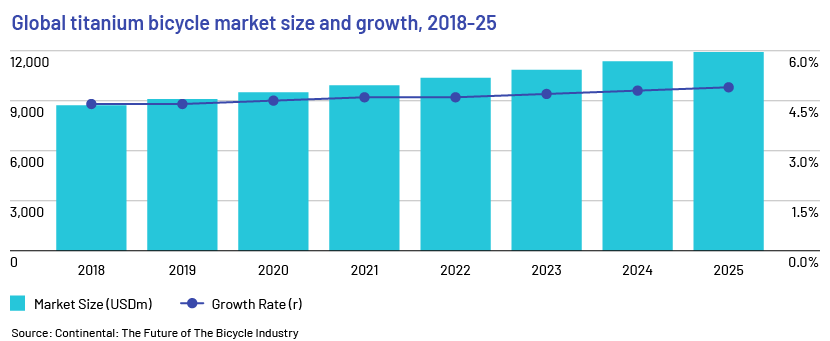

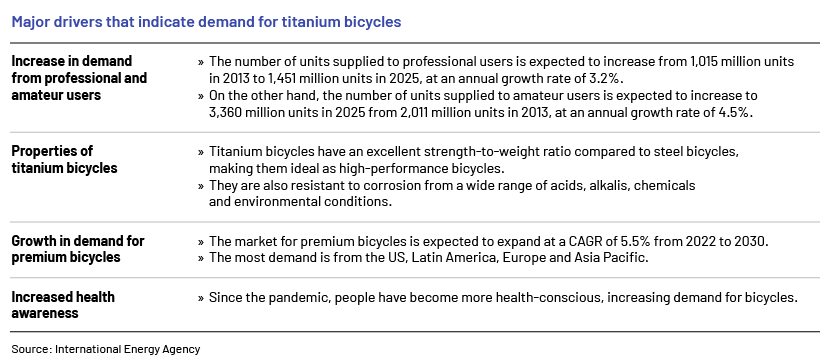

The global bicycle market was valued at USD8,715.1m in 2018 and is expected to grow to USD11,907.6m in 2025 at a growth rate of approximately 5.0%. As more people become health-conscious, especially after the pandemic, the bicycle market is likely to attract more demand than before.

Demand for titanium bicycles is expected to reach c.4.8m units by 2025, translating into a market size of USD 11.9 bn in 2025.

Conclusion

Titanium is a metal with a wide range of applications in many growing sectors. A number of countries are moving to reduce carbon dioxide emissions and need to rely on green technology to do so, with green hydrogen at its core. This indicates the titanium market is in a high-growth phase.

Titanium finds application in industries that prioritise a good strength-to-weight ratio, chemical stability and corrosion resistance. Its remarkable thermal properties, high strength-to-weight ratio and ductility contribute to its versatility. It is, therefore, expected to be used very similar to steel in a number of sectors.

Western nations reducing reliance on Russian titanium companies presents an opportunity for other countries to step in to meet the growing demand. Countries such as China, Japan and the US are well positioned to capitalise on this opportunity and maximise the benefits associated with expanding the titanium market.

How Acuity Knowledge Partners can help

We offer a pool of professionals experienced in the rare metals, power and energy sectors. We collaborate closely with clients, leveraging our expertise and developing customised strategies that enable them to capitalise on emerging trends and expand their market presence. Our comprehensive range of services includes market research and forecasting, market entry and due diligence support, opportunity evaluation, market access solutions, pipeline analysis, benchmarking and competitive intelligence.

By offering tailored research assistance and strategic guidance, we empower our clients to gain a competitive edge. Our dedicated team excels in providing valuable insights and tracking global sectors, enabling data-driven decision making and ensuring optimal outcomes for our clients.

(https://www.acuitykp.com/solutions/metals-and-mining/)

References:

-

https://www.marketresearchfuture.com/reports/titanium-metal-market-7482

-

https://blog.thepipingmart.com/metals/the-use-of-titanium-alloys-in-shipbuilding/

-

https://www.refractorymetal.org/application-of-titanium-alloys-on-ships/

-

https://www.mordorintelligence.com/industry-reports/titanium-alloy-market

-

https://pubs.usgs.gov/periodicals/mcs2023/mcs2023-titanium.pdf

-

https://www.mining-technology.com/news/china-russia-titanium-mine/

-

https://finance.yahoo.com/news/titanium-metal-market-size-worth-140000527.html

Tags:

What's your view?

About the Author

Shakun is an associate with nearly three years of experience in research and consulting, specializing in metals, mining, and critical minerals. At Acuity Knowledge Partners, he supports clients with a variety of strategic research initiatives. He holds a PGPM degree with a specialization in finance.

Like the way we think?

Next time we post something new, we'll send it to your inbox