Published on May 23, 2025 by Manas Manna

Introduction

AI in semiconductor manufacturing is transforming one of the world’s most intricate and aggressive sectors, constantly evolving in terms of innovation, quality, input costs and revenue generation. The sector faces numerous challenges from design issues and demand shifts to geopolitical tensions and supply-demand imbalances.

Using a variety of inputs, Generative and Agentic AI helps users create new and innovative content fast. These models are designed to be versatile and adapt to different types of data, enabling them to generate a wide range of outputs.

Even though the global semiconductor inductor evolving rapidly, the following are some of the challenges the industry is facing:

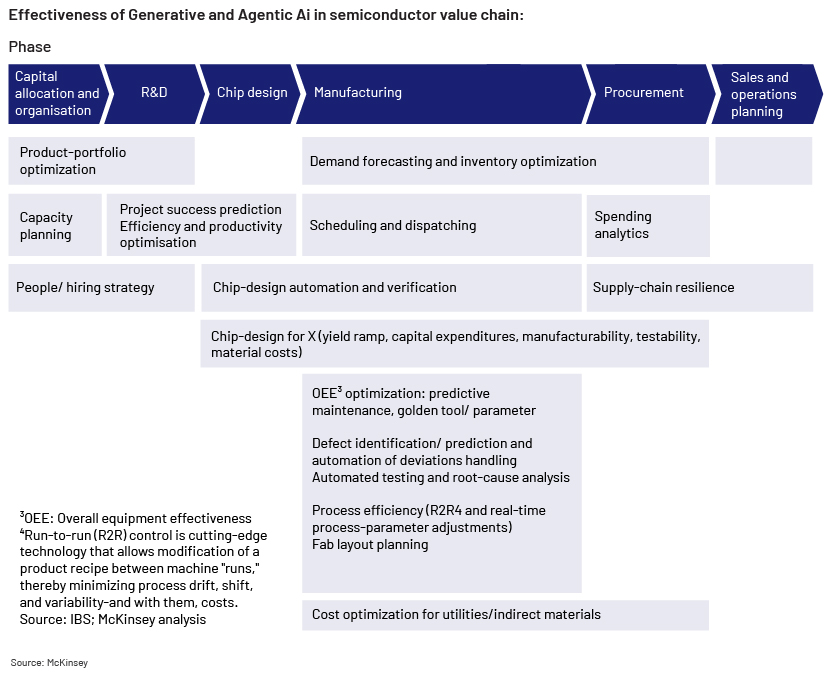

Generative and Agentic AI has the potential to help semiconductor players address some of the most critical issues they confront, paving the way for new opportunities for innovation and productivity

-

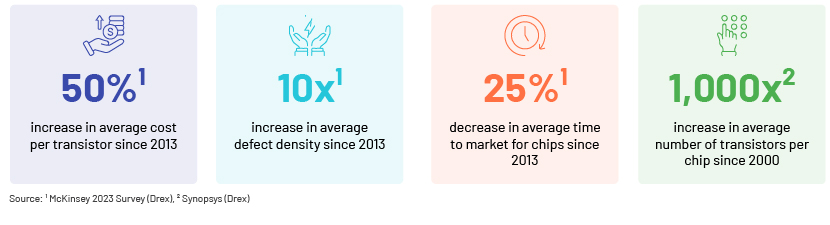

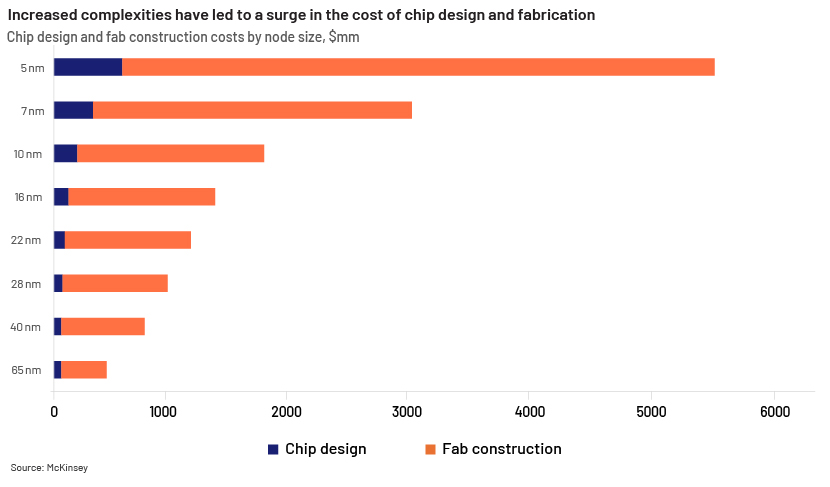

Rising costs: In the context of Generative AI in semiconductor industry, chip manufacturing costs can be effectively managed by optimizing designs and resource allocation.

-

Complexity: Chip design complexity has surged due to higher efficiency demands, increased component integration, heterogeneous architectures, and diverse application needs

-

Quality control: The quality of wafers depends on the material, process error, environment and human error. However, as particle size reduces below 10nm, error rates increase due to factors such as quantum effects, distortion and noise

-

Time to market: The time to market for wafers is influenced by factors such as cycle time, production time, test cycle time and supply-chain management. As chip use becomes more common and competitive, time to market becomes shorter and more crucial for success

It is interesting to see how semiconductor companies are capitalising on AI/ML to gain significant value, especially considering the substantial capex, operating expenses and material costs involved in the fabrication process. The most significant advantages of AI/ML would be realised in the R&D domain, which facilitates automation of chip design and verification.

How AI can help the sector overcome these challenges

GenAI has the potential to help address the above-mentioned challenges by enabling players to optimise processes, reduce costs and improve product quality. By leveraging ML algorithms, AI can analyse data and identify patterns to help semiconductor players make informed decisions about their operations:

-

Optimising chip design: By leveraging reinforcement learning, AI can optimise component placement or floor planning, reducing product development time from weeks to mere hours

-

Energy efficiency: AI is proving to be an invaluable tool in improving the use of energy in semiconductor fabrication processes. By exploring models and forecasting power consumption needs, AI can help reduce avoidable energy consumption and lower costs

-

Predictive maintenance: This is critical in the semiconductor sector, as even a small malfunction in equipment can lead to significant downtime and losses. AI helps address this issue by providing real-time monitoring of equipment and predicting when maintenance is needed

-

Simulated operations: AI has greatly influenced the semiconductor manufacturing sector by enabling simulated operations. With the help of this technology, facilities and processes can be designed and optimised more efficiently

-

Improving defect detection: Generative AI in semiconductor industry uses unsupervised learning (a machine learning technique) to help extract errors in semiconductor chips without prerequisite knowledge. With this technology, the accuracy of defect detection rises to 30% more than that of conventional methods, ensuring effective quality control

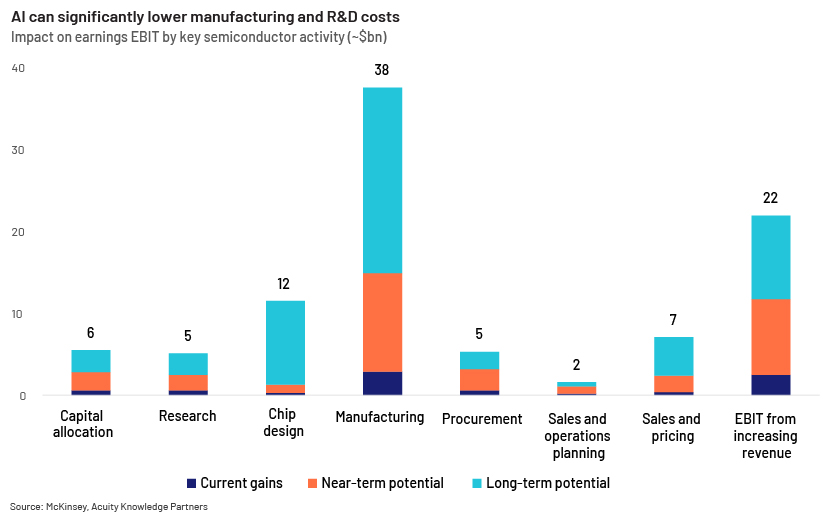

A McKinsey study has revealed that manufacturing is the biggest cost driver, and AI/ML use cases are expected to deliver the most value. The use of AI to reduce semiconductor manufacturing costs and starting the transition to autonomous manufacturing would lead to the most value creation.

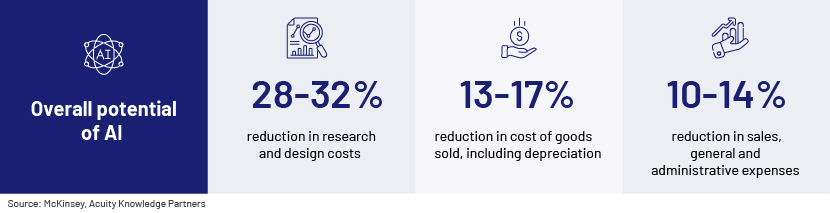

AI and ML also have the potential to significantly reduce the current R&D cost base. Experts predict that these technologies could lead to cost reductions of up to 28-32%, more than the improvement expected in manufacturing.

Other benefits of Generative and Agentic AI for the sector

-

Exploration of new materials: AI can help design new materials with unique properties that could not even be imagined previously. It can create particles or compounds with specific characteristics such as high conduction, thermal stability or biocompatibility, which could be game changing for several sectors

-

Development of new markets: AI has the potential to grow the market for semiconductor devices by creating customised offerings such as specialised sensors, processors or memory devices for different sectors

-

New innovations: AI can now help create a model that combines traditional data sources with new R&D data. By accelerating the overall semiconductor manufacturing process, manufacturers would achieve greater efficiency while reducing costs

Recent developments from major semiconductor companies

|

Nvidia aims to refine its design methodologies and establish a new precedent in the application of AI in technology development by introducing chatbots into its chip design framework. |

|

Synopsys has expanded its Synopsys.ai EDA suite, to improve engineering productivity for the semiconductor sector by bringing in the capability of GenAI across the full stack. It has partnered with various companies such as AMD, Intel and Microsoft to leverage the value of GenAI across the Synopsys.ai full EDA stack, from design and verification to testing and manufacturing. |

|

Samsung plans to use AI and big data technology in its chipmaking process to enhance productivity and refine product quality. It will seek to apply AI technology in DRAM design automation, chip material development, foundry yield improvement, mass production and chip packaging. |

|

Cadence tools introduced GenAI to chip and system design. The latest version of Cadence's Virtuoso Studio features the capability to move existing chip designs and IP from one generation of semiconductor manufacturing process to another via trained AI algorithms. |

Key Takeaways

Generative and Agentic AI is revolutionizing the semiconductor industry by significantly enhancing productivity and efficiency. It enables AI and ML technologies to identify patterns, classify information, and uncover insights from vast data sets. GenAI applications span the entire silicon design and manufacturing process. The surge in demand for GenAI applications is driving up the need for high-performance chips, prompting substantial investments in data centers and semiconductor fabrication plants. Overall, GenAI is poised to offer substantial benefits, such as reduced time-to-market, cost savings, and enhanced product quality.

How Acuity knowledge Partners can help

Acuity Knowledge Partners have been providing strategy research support to diverse stakeholders in the technology sector – tech corporates, tech advisory firms and tech-focused investors – for more than two decades. Accuity support helps various consulting clients to identify new opportunities and to stay competitive and compliant. Over the years, we have partnered with leading semiconductor companies, working closely with their corporate strategy, business development, and market intelligence teams to provide the information and analysis necessary to achieve their business objectives. We have a large pool of seasoned professionals who have been tracking the semiconductor sector for over 10 years and providing strategic research support across the value chain. (https://www.acuitykp.com/solutions/tmt-research-services/)

References:

-

Generative AI for Semiconductor Manufacturing: Challenges and Opportunities (DRex)

-

Driving Sustainability in Semiconductors: The Gen AI Advantage (LinkedIn)

-

Scaling AI in the sector that enables it: Lessons for semiconductor-device makers (McKinsey)

-

Trained on Chips, GenAI is Reshaping the Chip Industry (Analytics India Mag)

-

How Nvidia is using AI chatbots to craft smarter chips (Techwire Asia)

-

Samsung to apply AI, big data tech to entire chipmaking process (KED Global)

-

Latest Cadence tools bring generative AI to chip and system design (Techspot)

Tags:

What's your view?

About the Author

Manas Manna is a part of Acuity Knowledge Partners – Corporate & Consulting team with experience in strategy building and business research. His functional expertise includes strategic research, company and competitive intelligence, market entry analysis, growth strategy, market sizing, identifying business opportunities, and benchmarking. He also provided strategic recommendations to clients across various industries including Technology, Semiconductor, Consumer Electronics, etc. Manas holds an MBA in Marketing from Asia Pacific Institute of Management, India, and has a bachelor’s degree from The University of Burdwan.

Like the way we think?

Next time we post something new, we'll send it to your inbox